Tilt Switches

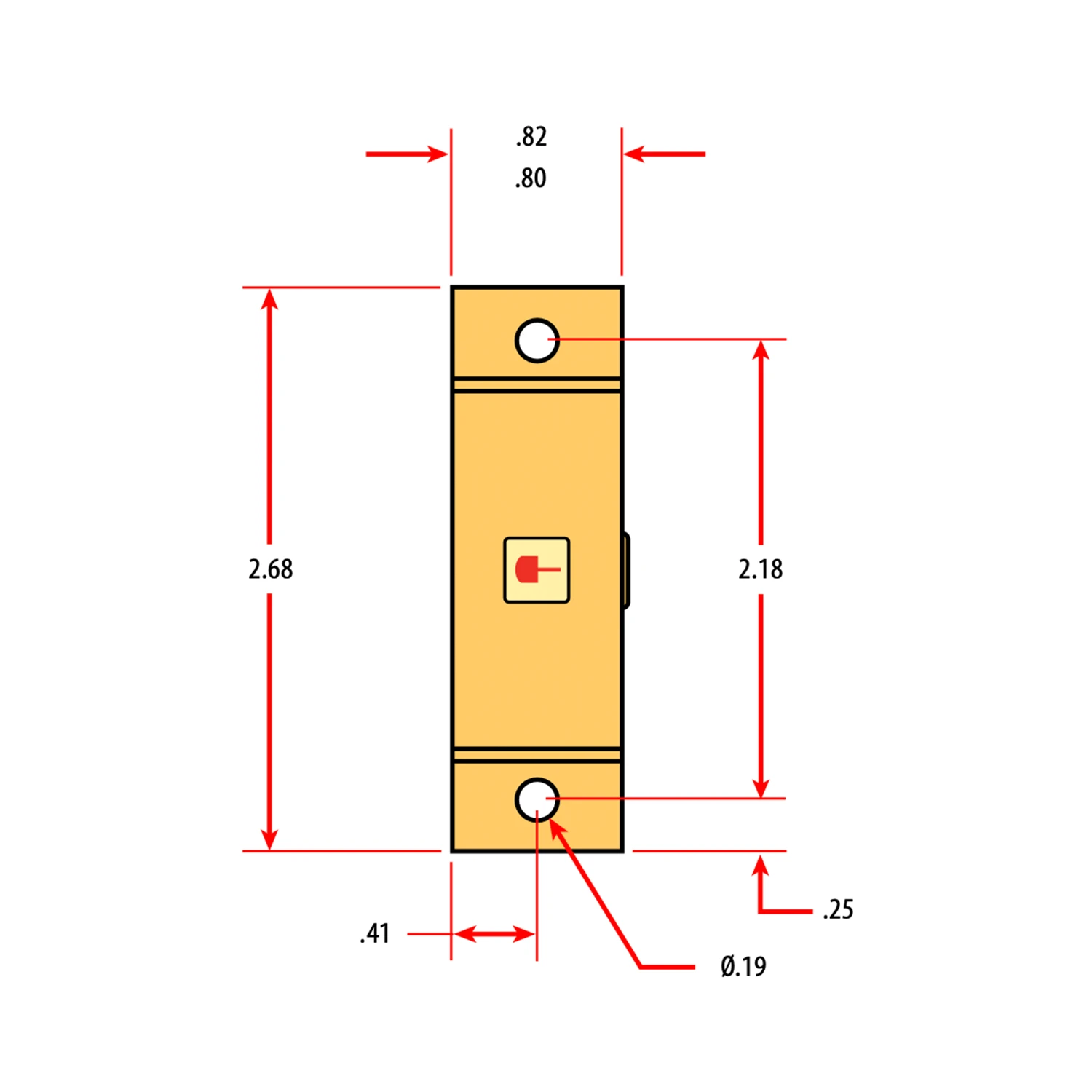

T1 Series

The T1 Unidirectional Tilt Switch is a non-mercury, RoHS-compliant industrial sensor designed for fine tilt switching. It utilizes Magnasphere’s patented magnetic switch technology for enhanced vibratory stability and is sealed against atmospheric and water ingress to ensure durability in harsh environments.

The switch complies with RoHS standards, ensuring environmental safety, and requires no standby power consumption.

The T1 tilt switch was designed to be the finest, environmentally sound alternative to mercury switches having field-configurable contact forms (A or B).

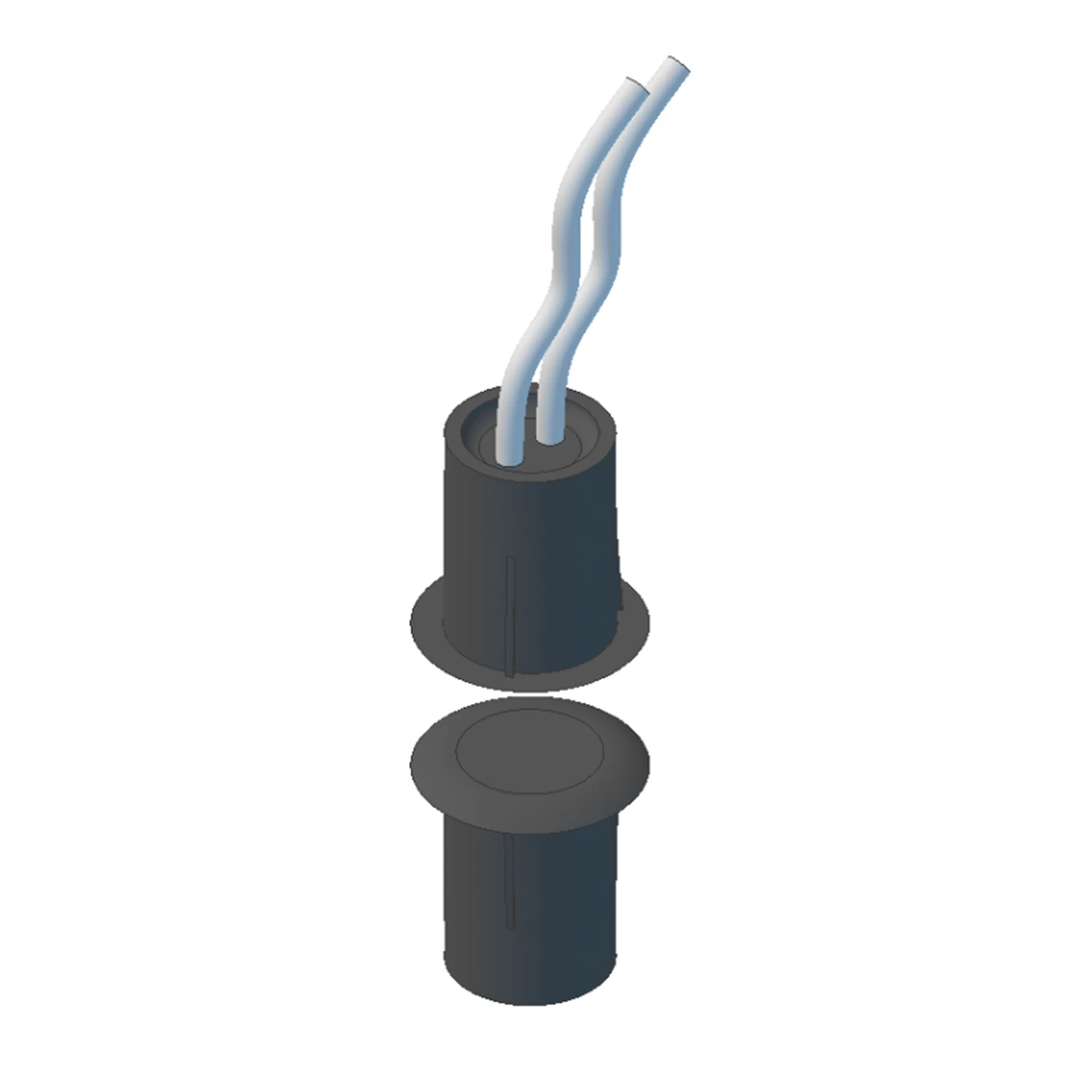

T3 Series

The T3 Omnidirectional Tilt Switch is a mercury-free, RoHS-compliant industrial sensor for precise tilt switching.

It employs Magnasphere’s patented magnetic switching technology, delivering superior resistance to vibration and shock.

The device is fully sealed to protect against moisture and contaminants, ensuring dependable operation in demanding environments.

The T3 can also be deployed as an accelerometer switch. RoHS-compliant and requiring no standby power, the T3’s characteristics make it a reliable choice for diverse industrial applications.

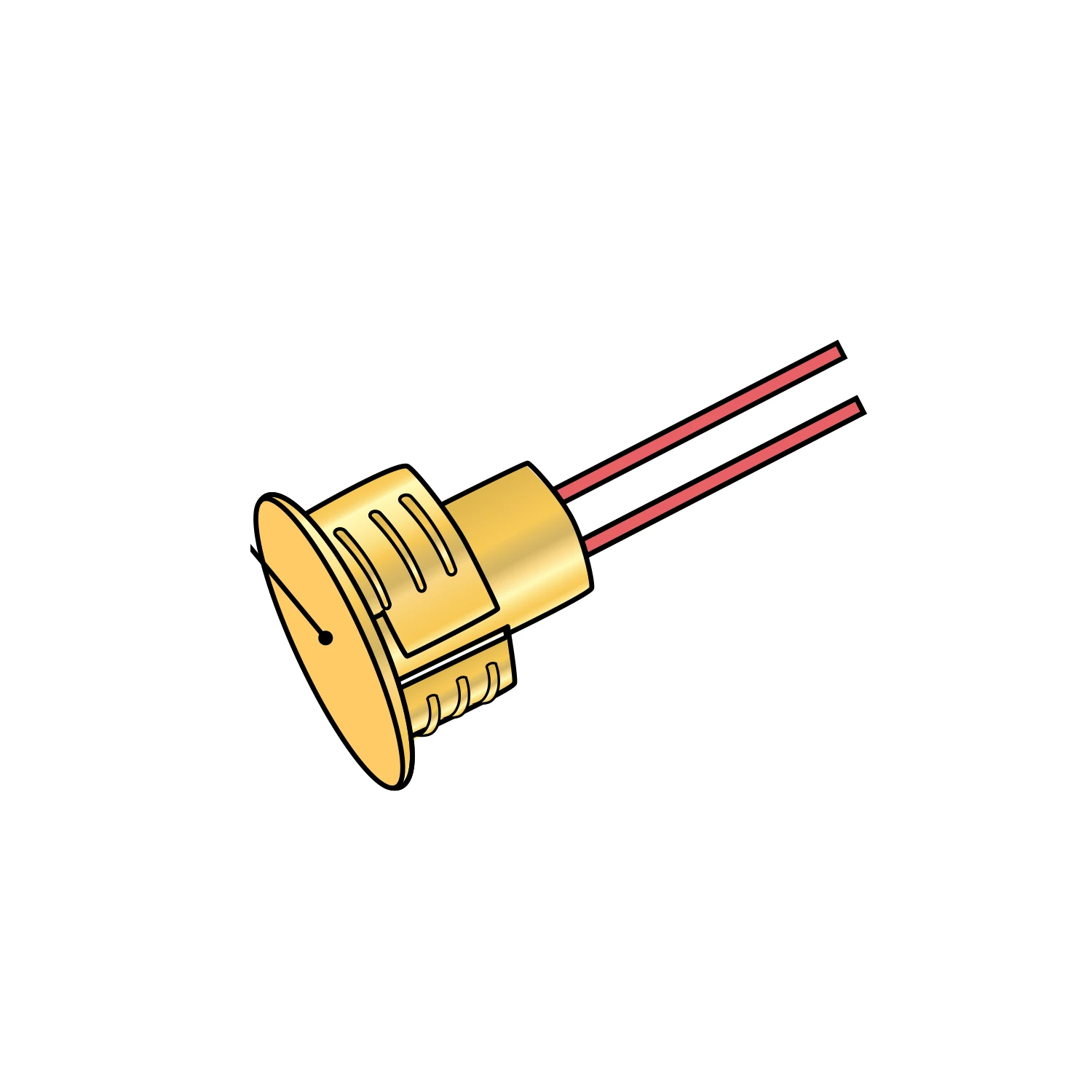

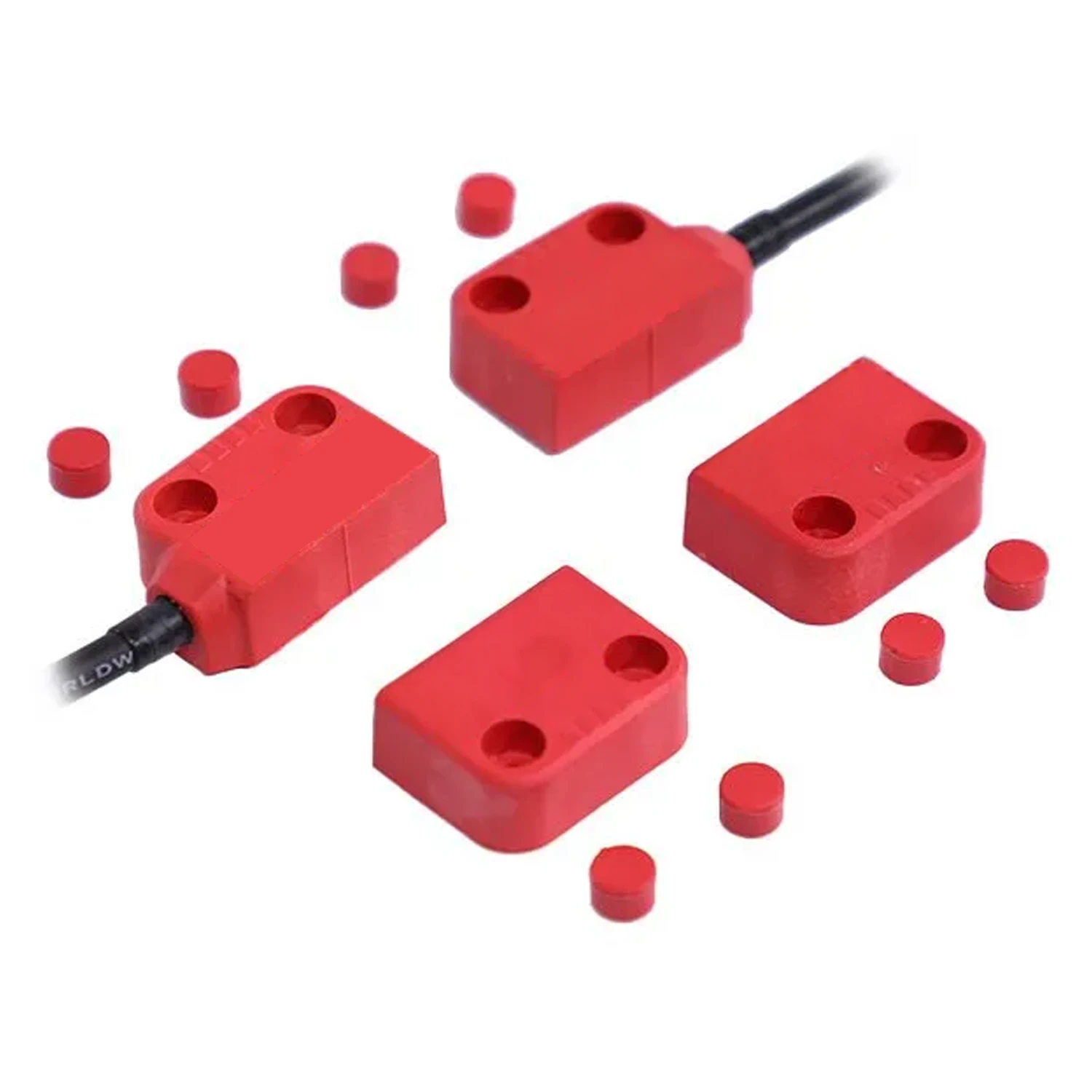

Magnetic Position Sensors (MPS)

Magnasphere’s proximity and tilt sensors are engineered for reliable, non-contact detection in demanding industrial environments. Utilizing patented magnetic switching technology, they offer high resistance to vibration, shock, moisture, and contaminants.

Housed in rugged or compact sealed enclosures, the range includes solutions for high-current switching, concealed installations, and harsh conditions requiring tamper resistance. These sensors are energy-efficient, requiring no standby power, and support flexible mounting configurations to meet diverse application needs.

With a focus on durability, safety, and precision, Magnasphere’s sensors deliver consistent performance and robust protection across a wide range of industrial and commercial use cases. Please contact us for your ferrous proximity, magnetic proximity, and non-mercury tilt sensing needs. See also Advantages of a mechanical switch over semiconductor technologies.

Custom Sensors

High quality custom sensors for demanding environments. We have been doing the work for decades, serving distinct needs by designing new sensors completely or developing specialty variants. We can customize electromechanical magnetic proximity, ferrous proximity, and non-mercury tilt switches and sensors. Whether it’s customized cabling, alternate housings, a new model to best fit your application, we are ready to assist your custom sensor needs.

Proximity Sensors

Frequently asked Questions

Why choose a proximity switch over a limit switch or microswitch?

- Limit and micro switches require a mechanical lever which suffers wear with each cycle of actuation. The mechanical lever or linkage also suffers degradation from environmental factors (such as salt, moisture, debris, and chemical exposure). Proximity technologies simply remove this point of failure from the assembly.

The mechanical lever or linkage also suffers degradation from environmental factors (such as salt, moisture, debris, and chemical exposure). Proximity technologies simply remove this point of failure from the assembly. - Limit and micro switches must be mechanically linked to the electrical contact, complicating ingress protection (if any protection from the environment was afforded the design). The lack of the material link or lever is a major design advantage of proximity switches against unwanted ingress of contamination to the electrical contact (which can enjoy hermetic sealing and longer operational life). The lack of the material link or lever is a major design advantage of proximity switches against unwanted ingress of contamination to the electrical contact (which can enjoy hermetic sealing and longer operational life).

What are magnetic proximity switches, and how do they function?

Magnetic proximity switches use the manipulation of a permanent magnet’s field to change the state of an electrical contact. The magnetic field is manipulated by paramagnetic (iron or steel) or magnetic “targets” affixed to the moving or placed object of interest. Basically, the magnetic field is the mechanical linkage for electromechanical proximity sensing –and it will not suffer the issues of a material linkage described above.

A proximity sensor should have three wires but most Magnasphere products have two --why?

Many proximity technologies are solid state technologies which require a supply and ground to function. This can greatly complicate wiring, design, and troubleshooting. Proximity switches (best understood as a class of proximity sensors) are simple electromechanical contacts which require only two wires; please click here for more advantages of contacts over solid state technologies.

How much power does a Magnasphere proximity switch use?

Most Magnasphere proximity technologies are switches, electrical contacts, which do not consume power at all; the electrical ratings describe the load that the switch can manage.